vickers hardness test and brinell hardness test difference|brinell to vickers hardness conversion : bulk Understanding the Vickers and Brinell Hardness Tests. Before diving into conversions, it’s essential to understand how the Vickers and Brinell hardness tests work. 1. Vickers . webVídeos Pornôs Com Negao Com Loiras. Mostrar 1-32 de 139959. 7:32. Loira gostosa traindo o marido com um negão pauzudo. ABrunaCarlos1. 96.3K Visualiz. 80% 7:19. .

{plog:ftitle_list}

Our website runs on 128-bit SSL (Secure Socket Layer) encryption and uses the most innovative PGP protocol to ensure safe and totally secure sensitive data transfer. Best legal and licensed online casino in Australia 2024! Play your favourite casino slots for real money! Fast payouts, bonuses and free spins!

There are three principal standard test methods for expressing the relationship between hardness and the size of the impression, these being Brinell, Vickers, and Rockwell. For practical and calibration reasons, each of these methods is . The three most well known and widely used hardness tests for metals today are Brinell, Rockwell, and Vickers. Here are the basic differences explained.

Understanding the Vickers and Brinell Hardness Tests. Before diving into conversions, it’s essential to understand how the Vickers and Brinell hardness tests work. 1. Vickers .What is the Difference between Rockwell and Vickers Hardness Test? 1. Testing Principle. 2. Indentation Shape. 3. Load Ranges and Accuracy. 4. Measurement. 5. Materials. 6. Accuracy and Precision. 8. Test Result . Vickers Hardness Test. Making use of a diamond indenter, the Vickers hardness test is done with less force and more accuracy than the Brinell test. By magnifying the surface of a metal, this test can target specific .

Brinell hardness testing is best for large and rough materials, and when a representative average hardness value is needed. Rockwell hardness testing is versatile, offers different scales, and is suitable for various materials, .The Vickers hardness test utilizes a pyramidal diamond in-denter to create an indentation on the material‘s surface. The diagonals (x and y axis) of the indentation are measured, and the . The most frequently referenced hardness tests in material datasheets are Rockwell, Brinell, and Vickers, with Rockwell being the most prevalent due to its quick and . Rockwell hardness testing, Brinell hardness testing, and microhardness testing are all methods used to verify heat treatment results. . It’s also critical to specify the correct load for Knoop tests because too-light .

Brinell Hardness The Vickers hardness test utilizes a pyramidal diamond in-denter to create an indentation on the material‘s surface. The diagonals (x and y axis) of the indentation are measured, and . Test Cycle for Depth Difference Methods 1. The preload is applied to the sample and held for a specific time. For Rockwell methods the . The Brinell hardness test is ideal for measuring the hardness of metals with coarse or inhomogeneous grain structures, such as cast iron and softer metals like aluminum alloys. . Vickers Hardness Test. . By understanding the differences among various hardness testing methods, you can select the right hardness test method for a specific .

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf . The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small parts, thick coatings and materials . Vickers microhardness testing assists with characterizing case-hardened depths, dimensions of weld heat-affected zones, differences in microstructural phase hardness and metallurgical phase segregation, among other properties. ASTM E384 and ISO 6507 cover the standard test method for Vickers microhardness testing. Converting Between ScalesA variety of hardness-testing methods are available, including the Vickers, Brinell, Rockwell, Meyer and Leeb tests. Although it is impossible in many cases to give an exact conversion, it is possible to give an approximate material-specific comparison table for steels .

Hardness tests of metals are essential to manufacture reliable big machines and automobiles. The hardness test should be first selected according to the needs of the material. You can find answers to questions about the Brinell and Rockwell in the article, as we have clarified the difference between the two tests.The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. . the difference between the largest and smallest measured diameters for the same indentation shall not exceed 1% of the indenter ball diameter unless it is specified in the product specification, such as for an .

The Brinell hardness test is named after its inventor, Johan August Brinell. It involves applying a constant load or force to a spherical indenter made of hardened steel or carbide onto the surface of the material being tested. . The difference between HBS and HBW is the indenter. . The Vickers hardness test utilises a diamond pyramid .The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is . It outlines the testing method, equipment, calibration, and procedures for determining the Brinell hardness of metallic materials using test forces between 1.96 N and 29420 N. ASTM E10 is an American Society for Testing and Materials (ASTM) standard that specifies the standard test method for Brinell hardness of metallic materials.

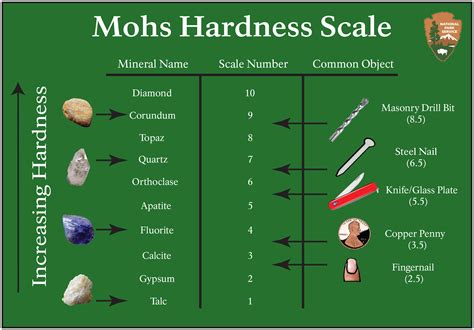

vickers hardness to mohs scale

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .Vickers Hardness Test Making use of a diamond indenter, the Vickers hardness test is done with less force and more accuracy than the Brinell test. By magnifying the surface of a metal, this test can target specific microstructural constituents like martensite or bainite, or assess the quality of heat treating or surface hardening operations.

Artificial Light Color Fastness Tester factories

The result is given in HV (Vickers hardness). Brinell Hardness Test: Typically used for softer materials, this test involves pressing a ball indenter into the material and measuring the indentation. Results are given in HB (Brinell hardness). . Key Differences. Hardness is about a material’s resistance to surface deformation and wear, while .DEFINITION OF THE BRINELL HARDNESS TEST The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His .

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for .Hardness testing is one of the most widely used material testing methods. Static hardness measurements are convenient for accurately determining the hardness. What is Brinell Hardness? Brinell hardness (HBW) is the ratio between the .Two common hardness tests are used in the industry: the Rockwell scale and the Vickers scale. Both test the surface of a material, but they are used for different purposes. The Rockwell hardness test measures the hardness of all metals except in conditions where the structure of the test sample would cause too much variations, or the indentations formed would be too .Rockwell Hardness Test 3.2. Brinell Hardness Test 3.3. Vickers Hardness Test 3.4. Knoop hardness 3.5. Shore 3.6.Others 3.6.1. Mohs Hardness: 3.6.2. Barcol Hardness . as the BHN goes above 650 the tungsten carbide ball begins to flatten out and the BHN values indicate a greater difference in hardness than there actually is, while above 739 the .

Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. . See also: Vickers Hardness Test. See also: Knoop Hardness Test. References: Materials Science: U.S. Department of Energy .The Brinell test measures the width of the indentation using a microscope. This measurement is then converted into a Brinell hardness value – the ratio between the applied force and the surface of the indent – using the Brinell hardness scale. Some of the advantages of the Brinell Hardness Test include: Simple surface preparation What is Brinell Hardness Test? The Brinell hardness test is the method measuring hardness through measuring the diameter of the indentation left by an indenter or other materials of a specified diameter, under a certain load into the surface. The Rockwell method is the most commonly used and versatile hardness test. Three common methods are Brinell, Rockwell, and Vickers hardness tests. In this article, we will compare these methods to help you choose the most suitable one for your testing needs. Brinell Hardness Test: The Brinell hardness test, named after Swedish engineer Johan August Brinell, is widely used for testing soft to very hard materials. In .

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . Brinell Hardness numbers in parentheses are outsite the range (HB>630 .The Rockwell test is a quick and direct process, while the Vickers hardness test is a slow process and requires other optical devices such as a microscope to measure the hardness of the object. Related Article: Hardness Test Comparison: Vickers vs Rockwell. Related Article: What is the Difference between Rockwell, Brinell, and Vickers?

The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Microhardness test procedure, ASTM E-384, specifies a range of light loads using a diamond indenter to make an indentation.

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.

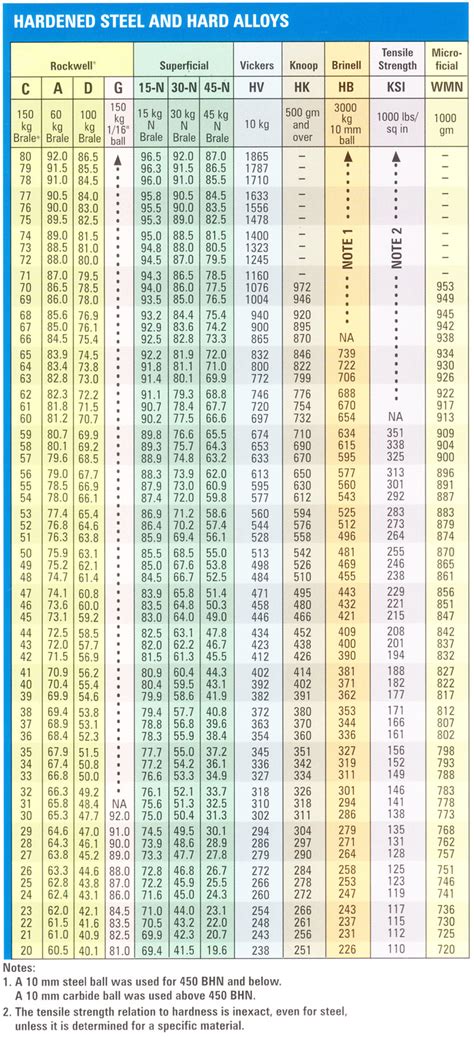

rockwell hardness scale comparison chart

rockwell hardness comparison chart

Resultado da Roxor Gaming was formed in September 2019 as a B2B content supplier. We may seem relatively new to the industry, but Roxor Gaming has built casino content for over 20 years as part of Gamesys (a Ballys’ Corporation Company). As a result, we already have the history, the scale, and market .

vickers hardness test and brinell hardness test difference|brinell to vickers hardness conversion